Structural modal analysis¶

This example shows you how to conduct a 3D transient structural analysis for an assembly. Modal structural analyses use FrontISTR as the default solver. It also supports using CalculiX or Elmer FEM as a solver.

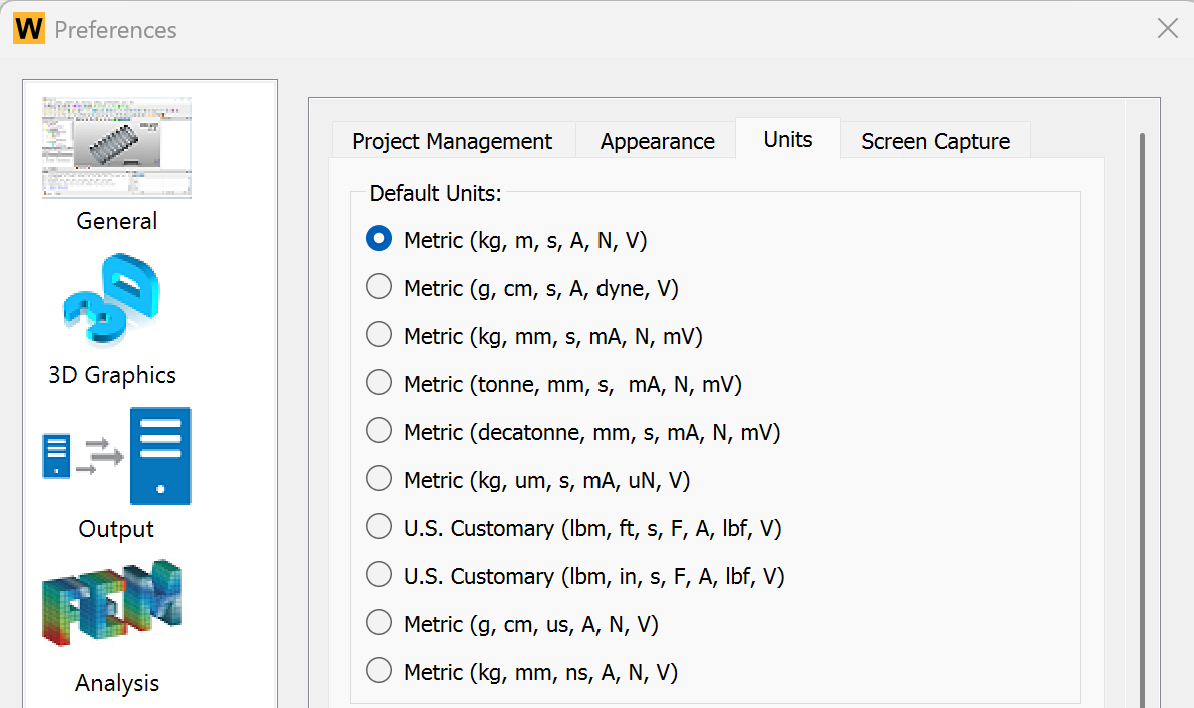

Selecting units¶

In the beginning, we select the MKS unit system for the subsequential simulation. Clicking Preferences from the Toolbar or Menu, and setting the Metric (kg, m, s, A, N, V).

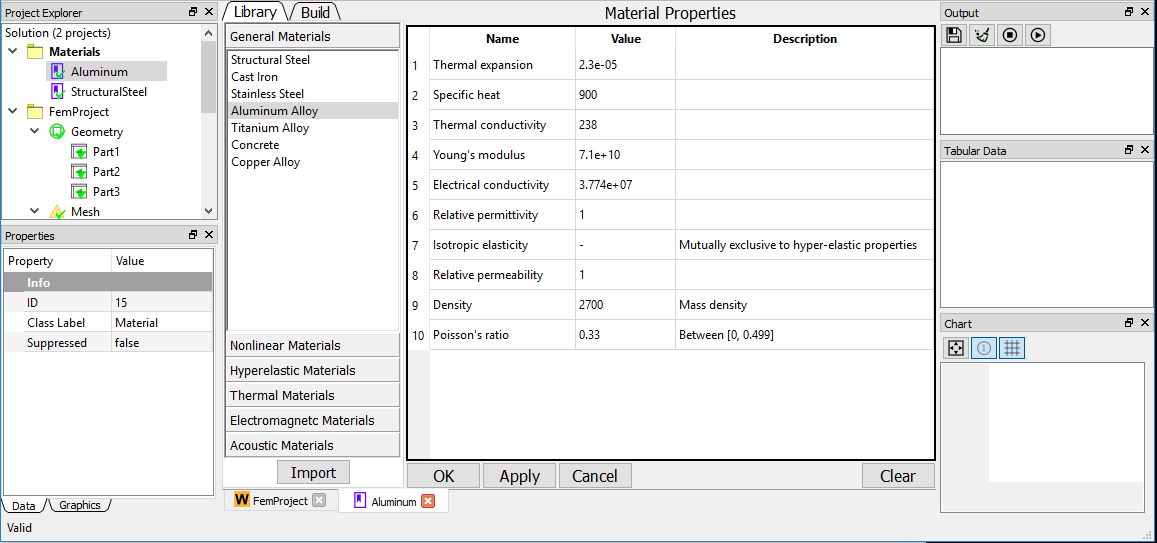

Defining materials¶

In this multi-body analysis, we assign Structural Steel and Aluminum materials to different parts. Since a Structural Steel object is already added as you initialize a FEM Project, you only need to insert an aluminum material object by clicking Add Material from Toolbar or FEM Menu.

To edit the material properties, you can double-click the Material object, or right-click on the Material object and select the Edit command from the context menu. In the material editor, you select the Library tab > General Materials > Aluminum Alloy, then click Import button or double-click the Aluminum Alloy entry. Click the OK to save and exit the material editing.

You can rename this new material object to Aluminum by press F2 key or right-clicking.

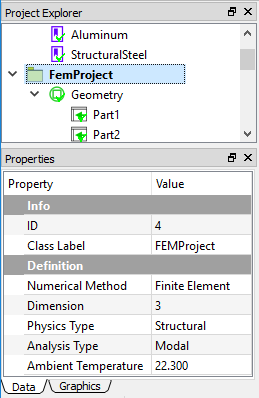

Specifying analysis¶

In the Properties View of the FEM Project object, you set the Analysis Type property to Modal. A Modal Structural analysis is defined as shown in Figure below.

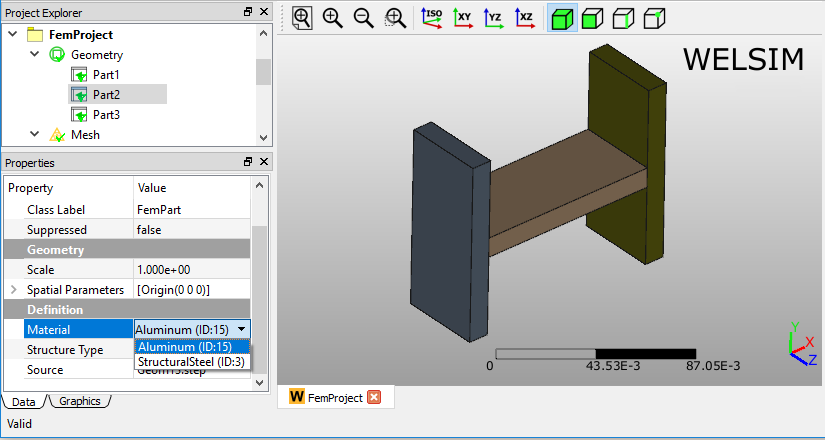

Preparing geometry¶

Next, you can import the geometry file “h_section_multibody.step” and assign the materials to the corresponding parts. Three Part objects in the Geometry group represent three bodies in the Graphics window, respectively. You assign the Aluminum material to the Part2, which is the connection body in the middle, the rest bodies are assigned with Structural Steel material.

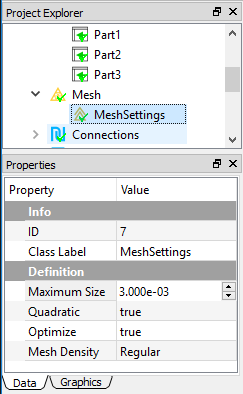

Setting mesh¶

To obtain a fine mesh for the analysis, you set the Mesh Settings properties Quadratic to True, and Maximum Size to 3e-3, as shown in Figure below.

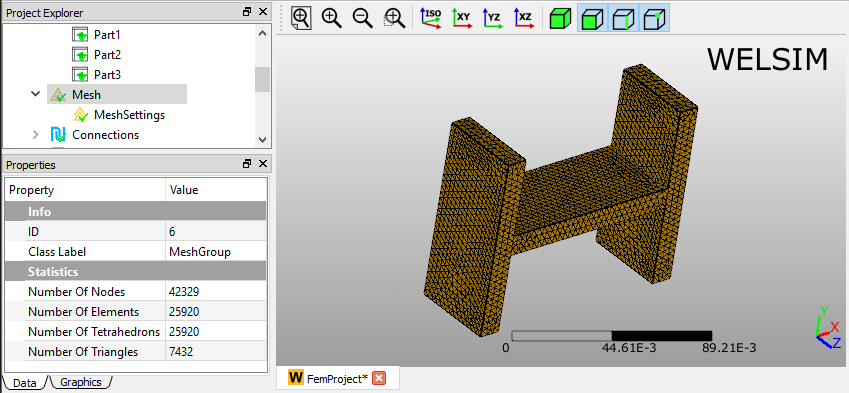

Clicking the Mesh command from the Toolbar or FEM Menu, you can mesh the geometries. There are 42,329 nodes, and 25,920 Tet10 elements generated as shown in Figure below.

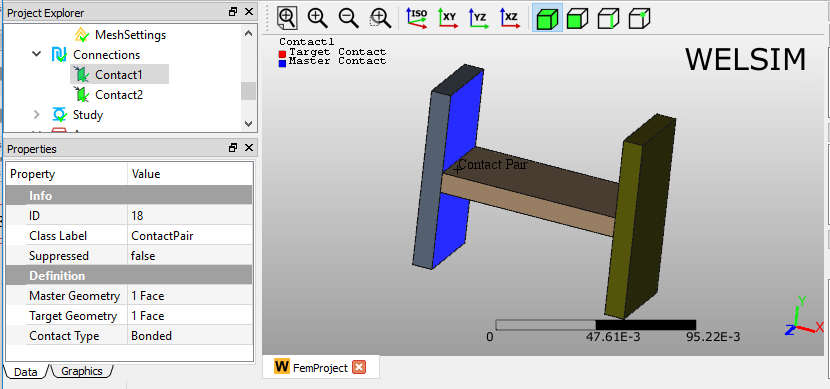

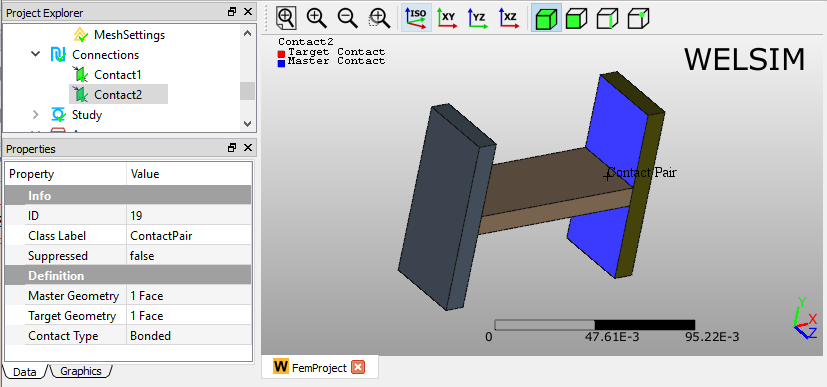

Specifying contacts¶

Next, you need to define two Contact Pairs to bond the three parts into one uni-body for the analysis. Clicking the Add Contact command from the Toolbar or FEM Menu, you add two Contact Pair objects into the tree. You can rename these two objects to Contact1 and Contact2, respectively. Then you select the surfaces for Master and Target Geometry properties.

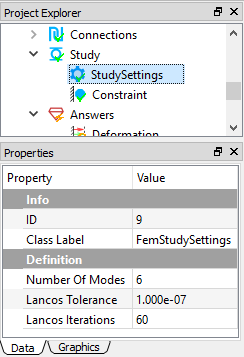

Defining analysis settings¶

In the Properties View of Study Settings object, you can define the analysis details such as Number of Modes. Here, you can use the default settings as shown in Figure below.

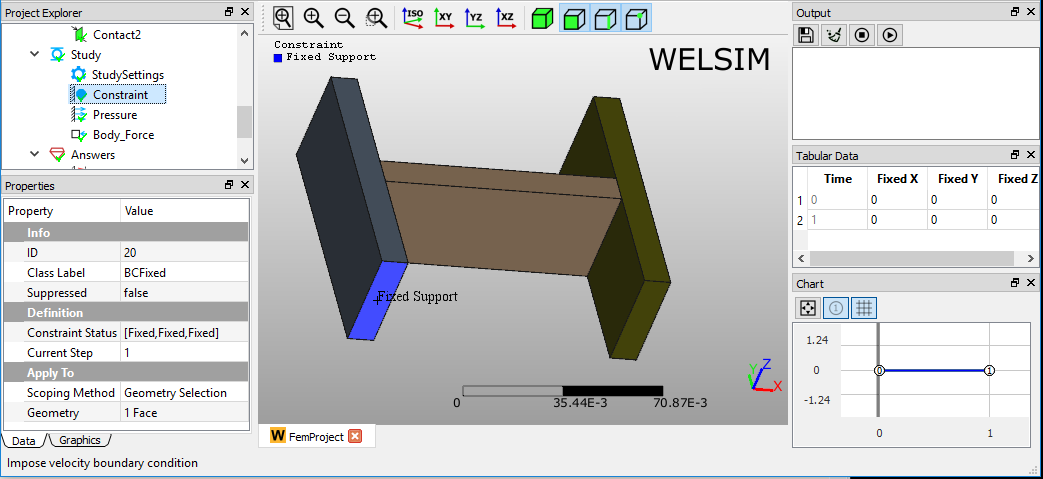

Imposing boundary conditions¶

In this modal analysis, you impose a Constraint (Fixed Support) boundary condition, which can be processed by clicking the corresponding commands from the Toolbar and Structural Menu. In the Properties View of the Constraint object, select the left bottom surface for the Geometry property.

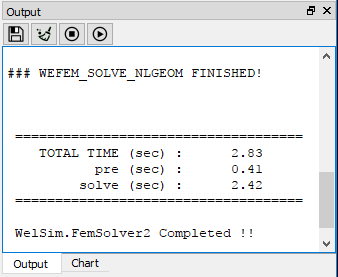

Solving the model¶

To solve the model, you can click the Compute command from the Toolbar, FEM Menu, or right-click on the Answers object and select Compute command from context menu. Depending on the complexity of the model, the solving process can be completed in seconds to hours. The Output window displays the solver messages and indicates the status of the solving process.

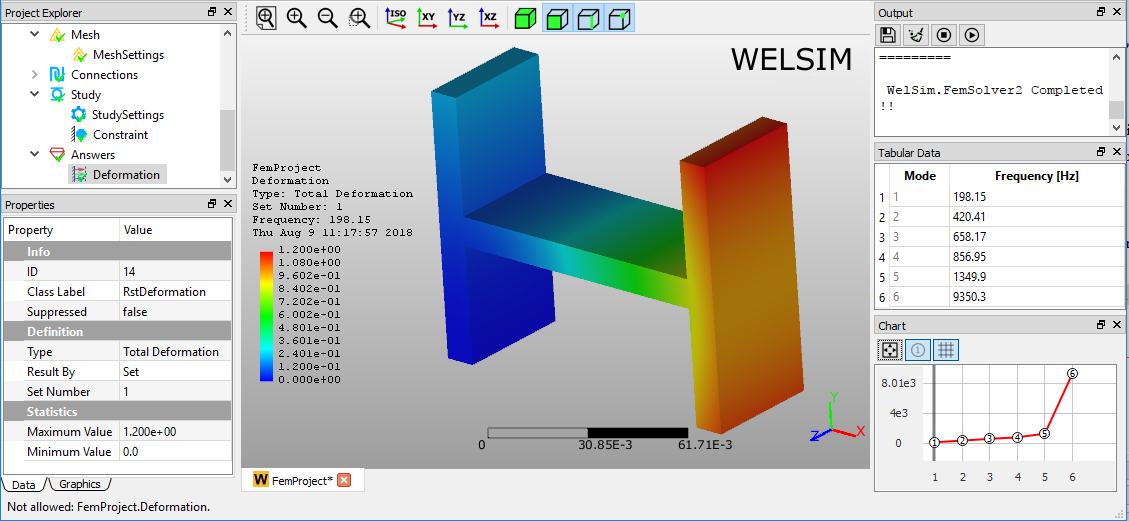

Evaluating results¶

To evaluate the deformation of the structure, you can add a Deformation object to the tree by clicking the Deformation item from the Toolbar, Structural Menu. A result object may provide multiple sub-result types. For example, a Deformation result object allows you to specify one deformation type from the candidates Deformation X, Y, Z, and Total.

After setting the Type property to Deformation Z, double-clicking on the result object displays the resulting contour in the Graphics window as shown in Figure below. You also can click the Evaluate item from the Toolbar or FEM Menu to evaluate the result.