Structural¶

Statically inteterminate reaction force analysis VM001¶

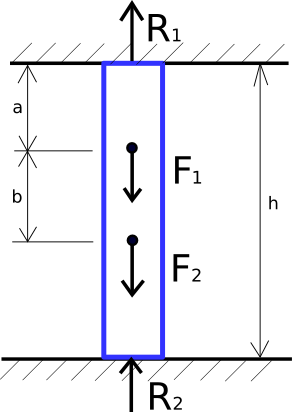

An assembly of three cylinder bars is supported at both end surfaces. Forces \(F_{1}\) and \(F_{2}\) is applied on the middle of the assembly as shown in Figure [fig:ch5_vm_001_schematic].

The input data about material, geometry, and loads are given in Table [tab:ch5_vm_001_parameters].

| Material Properties | Geometric Properties | Boundary Conditions |

|---|---|---|

| Young's Modulus E=2e11 | h=10 | \(F_{1}\)=2000 |

| Mass Density \(\rho\)=7850 | a=3 | \(F_{2}\)=1000 |

| Poission's Ratio v=0.3 | b=3 |

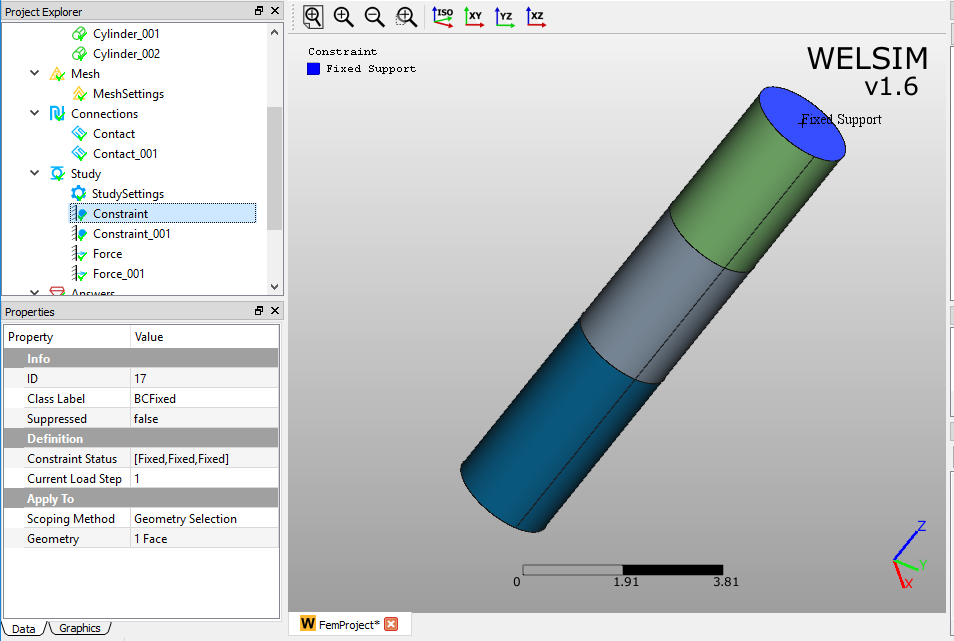

The geometries and imposed boundary conditions are shown in Figure [fig:ch5_vm_001_bc].

The result comparison is given in Table [tab:ch5_vm_001_result].

| Results | Theory | WELSIM | Error (%) |

|---|---|---|---|

| Z Reaction Force at Top Fixed Support | 1800 | 1810 | 0.556 |

| Z Reaction Force at Bottom Fixed Support | 1200 | 1202 | 0.167 |

This test case project file is located at [vm/VM_WELSIM_001.wsdb].

Rectangular plate with circular hole subjected to tensile pressure VM002¶

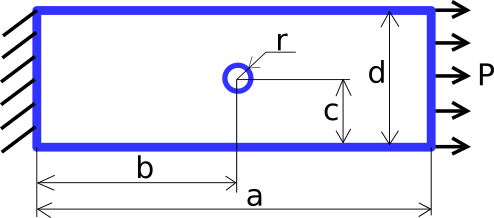

A rectangular plate with a circular hole is fixed along one of the end faces. A tensile pressure load is imposed on another end face as shown in Figure [fig:ch5_vm_002_schematic].

The input data about material, geometry, and loads are given in Table [tab:ch5_vm_002_parameters].

| Material Properties | Geometric Properties | Boundary Conditions |

|---|---|---|

| Young's Modulus E=2e11 | a=15 | Pressure P=1e4 |

| Poission's Ratio v=0.3 | b=7.5 | |

| c=2.5 | ||

| d=5 | ||

| thickness=1 |

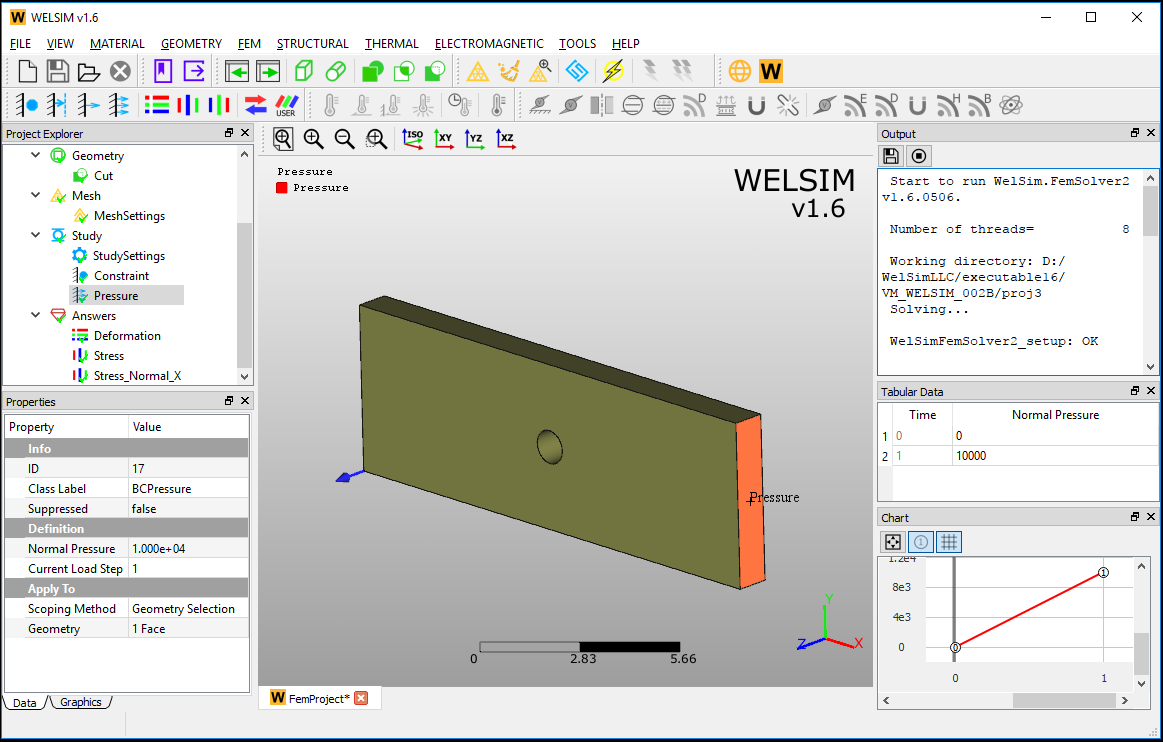

The geometries and imposed boundary conditions are shown in Figure [fig:ch5_vm_002_bc].

The result comparison is given in Table [tab:ch5_vm_002_result].

| Results | Theory | WELSIM | Error (%) |

|---|---|---|---|

| Maximum Normal X Stress | 3.125e4 | 3.156e4 | 0.992 |

This test case project file is located at %Installation Directory%/vm/VM_WELSIM_002.wsdb.